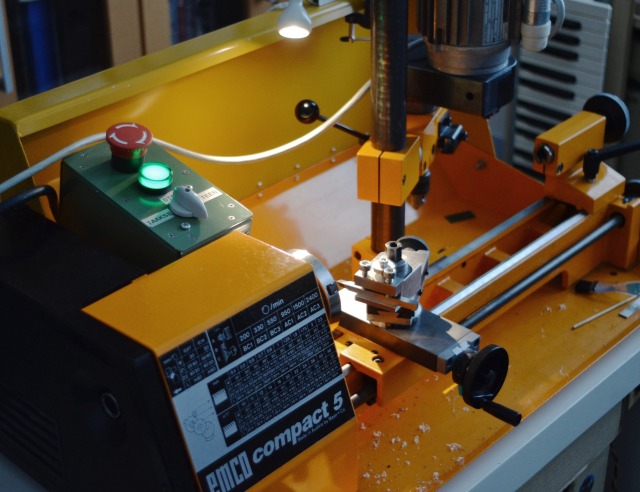

My Emco compact 5 lathe/mill/drill

Related: My Taig ML II

It takes about the same footprint as my Taig while naturally being a bit bulkier and taller with the chip pans and milling column. Maybe I'll get to the portable lathe project with the Taig.

What it's like

It's a benchtop lathe, somewhere between the Unimat and Maximat ranges or so. The machine is marked, as these are, "Made in Austria by Maier+Co". I think these were made in 1970-80's range. Cast iron and steel construction and design much like bigger lathes. There's perhaps a serial number on the bed, but I don't have a dating source or decoding ideas.

There's some story on the lathes.co.uk Emco Compact 5 page. It's nominally 65 x 350 mm capacity lathe with 16 mm bore. The bore is a nice step up from Taig's 8 and change. It has MT2 and MT1 tapers and the tool sizes vary a bit depending on the tool holding and mounted options. 6 mm and 8 mm seem to be the norm. I have a QCTP for it, which allows easy center height adjustment anyway. I also got quite a few toolbits, so there isn't a huge pressure to share and/or make new yet.

The spindle has register surfaces and 3 and 4 hole bolt circles plus the taper. It does not have nose threads. Instead, things mount on some (DIN standard) 3 or 4 hole bolt pattern. The milling head has M14 threads like many other small Emco machines, but no taper.

The tailstock locking bolt has been changed out for a locking lever. There is also copper plate on the motor to shield it from hacksaw scratches and rubber mats under some mounting points to help quiet down the vibration. AC motors do make some rumble, but otherwise it's a fairly quiet machine.

This also seems to be a slightly improved model with backlash adjustable longitudinal and cross-slide nuts.

Equipment

Probably most of the original equipment that was available:

- Compound slide

- Three jaw chuck

- Four jaw ind. chuck (x2)

- Chuck mount adapter

- Dividing attachment / Indexer (back)

- ESX25 collet chuck, both M14 and three-bolt

- ESX25 collets, set of 14 in a beech box

- Live center, dead centers MT1/MT2, arbors

- Slitting saw mandrel, M14 and slitting saws (7) plus adapters for two hole sizes

- Milling vise

- Milling table and clamps

- Drill chucks on Morse arbors (3)

- M14 drill chuck

- Morse adapters for M14, B10

- QCTP with 6 holders

- Original tool clamp x 2, plus block

- 2-way toolholder (view2)

- Threading gear set, probably complete

- Traveling and fixed steadies

- End mills

- Spare belts, extra shear pins, and c clips

- Drill bits, lots of drill bits

- HSS toolbits, various

- Bolts, lots of bolts. Also nuts.

- Manuals on loose pages and scans

Unusual equipment:

- Circular saw attachment (table, guides, and sawblade/arbor for headstock)

- Hand crank for spindle

- Fold-down chip guard

- Proxxon die grinder holder

- Custom faceplate, original dog

- Interchangeable tip tool and tips

- Interchangeable tip tool with no extra tips

- Interchangeable tips with no tool

Most sources seem to say the ESX25 collet system is compatible with ER25 ¹ ² . Possibly, they stand for E collet improved by Rego-Fix and Schaublin Xsomething respectively. There are a few other lines and markings as well. This would mean new collets are commonly available in varying quality and price points. The set is quite comprehensive and almost unused, though. Materials say the set has 14 collets although there are 5x3 slots in the box. There is a set of 15 ESX25 collets for sale, though. The originals are 1.5 - 14 mm and the new set is 2 - 16 mm.

Problems

Looks like the switch box limits the motor movement somewhat, making speed changes a bit tricky, but I've managed so far. The motors are not rated for continous use (meaning they are small for their power) and they get hot fairly fast. Just avoid long sessions and take breaks. That should suit the hobbyist just fine.

Projects

Meanwhile, there are other machining projects of mine on the Taig page and in blog posts.

- 1/4" 20 TPI screw to practice threading

- Body barrel for an outlet box latch

- Neck joint for a broken Barbie (or barbie-like thing)

- Cut hex head bolts for the collet chuck (done)

- Flex coupler from hose and brass clamps (not usable)

- Various wheels for round belt

- Rail for work light and other extras

- Nylon plugs threaded 5/8x11

- Decorative "Gold bolt" of brass

- Brass knobs for tractor

- Spindle depth stop

- Small slitting saw arbor

- Gear cutting arbor

Plans and ideas

- Take pictures, test things and set stuff up

- Work lighting (temp done), perhaps camera mount

- Spindle spider(s)

- Dial indicator mounts

- Depth stop for carriage. I really miss one.

- Get some parallels and possibly other clamping bits

- Could I mill some V blocks to start with?

- Milling guards

- Maybe a fly cutter

- Worm gear hobbing! (YT video)

- Oldham coupler

- More spur gears

- Portable lathe

- Tool grinder or jigs for bench grinder

- Small belt sander, disc sander