Mounting the Taig lathe

Posted at 2016-04-01.

So, I have a fresh Taig lathe that I "need" to set up.

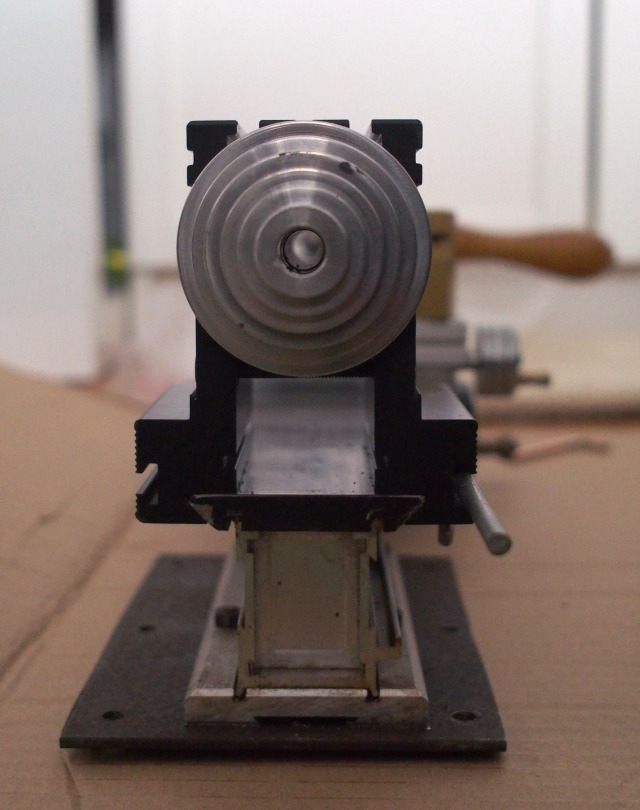

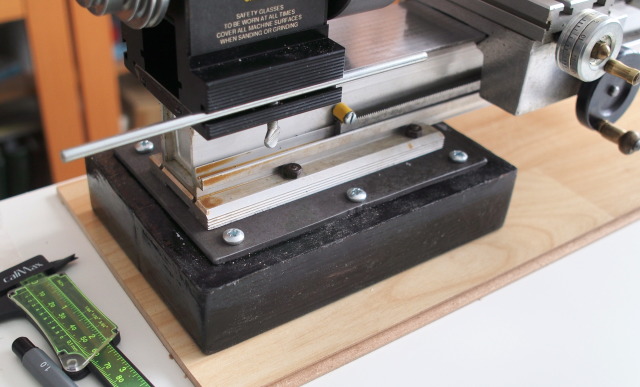

The lathe came with a drilled steel plate that had a lot of surface rust and that was also slightly warped. I cleaned it and left it with a phosphated grey surface. I then made a block out of two pieces of laminated wood and painted it black. Finally I bolted the block to some floor laminate and the steel plate to the lathe and finally to the block. Quick and dirty, but that should do for now.

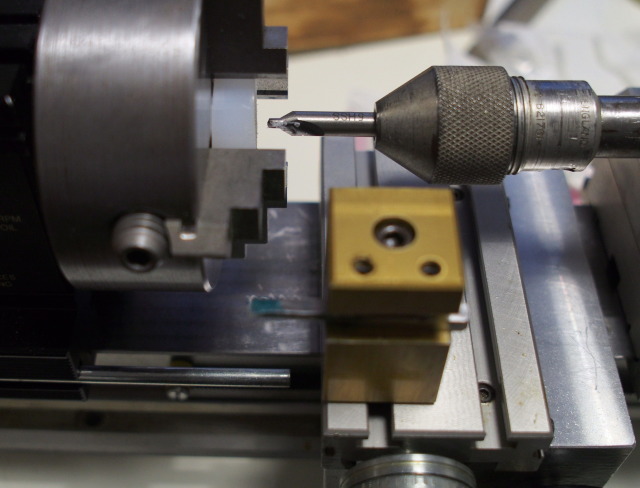

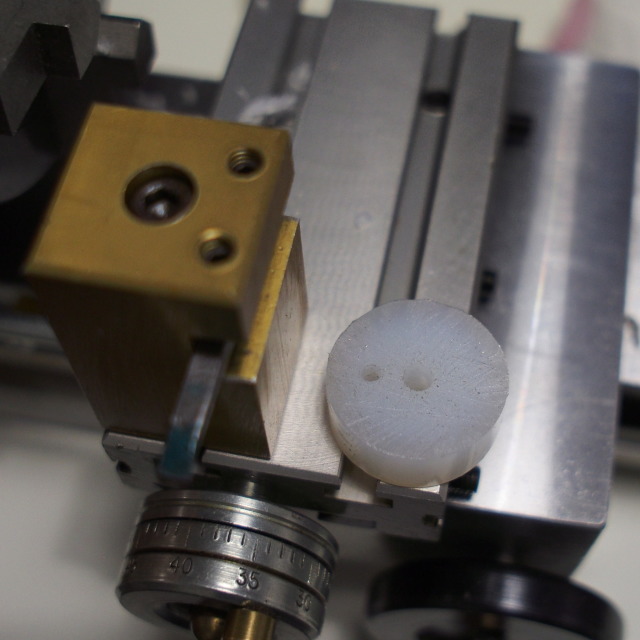

I had to take a few first chips by hand, so I tried a center drill in PA6 (Nylon) rod I bought locally earlier.

Sawing the rod is a chore, but doable. Hacksaw might be faster than the ryoba I usually use for plastics. Drilling works out quite nice if you don't get stuck. Some holes can be a pain. Tapping M3 worked out nice.

Turning with the Unimat even seems to work. I think the flex and uneven feed rate (handwheel) cause some chatter. PA is very bouncy material and general advice is very sharp tools and high feeds. You can go fast if heat doesn't build up.

Next things was to find a motor for the Taig and a belt for transmission. I could use the motor pulley if I can mate it to a motor or I could turn it into a jack shaft. Finding the skinny 3 mm belt is probably not going to happen without ordering one. I might do that one day, but for now I found a local source for PU belt that can be welded together. This is often sold as spares for small (watchmaker, Unimat) lathes. I bought 2 mm belt (no 3 mm in stock), welded a small loop, and used a handheld drill motor with a pressed PA pulley to turn. Very ghetto and non-usable, but at least it spins and belt slip seems controllable. Also, I had all the parts at hand, so this is a start.

Power supply and/or speed control is a definite missing link with this setup. It could be refined to work before moving to a better one. Better one being perhaps an order for a BLDC and ESC and making mounts. If I can make a mount that lets me swap to the OEM M500 type belt later, that would probably be best.

Links

- Main Taig page

- Blog: Taig running test

- Blog: Taig arrives

- Taig tools

- Peatol (UK/EU dealer)