Taig running test

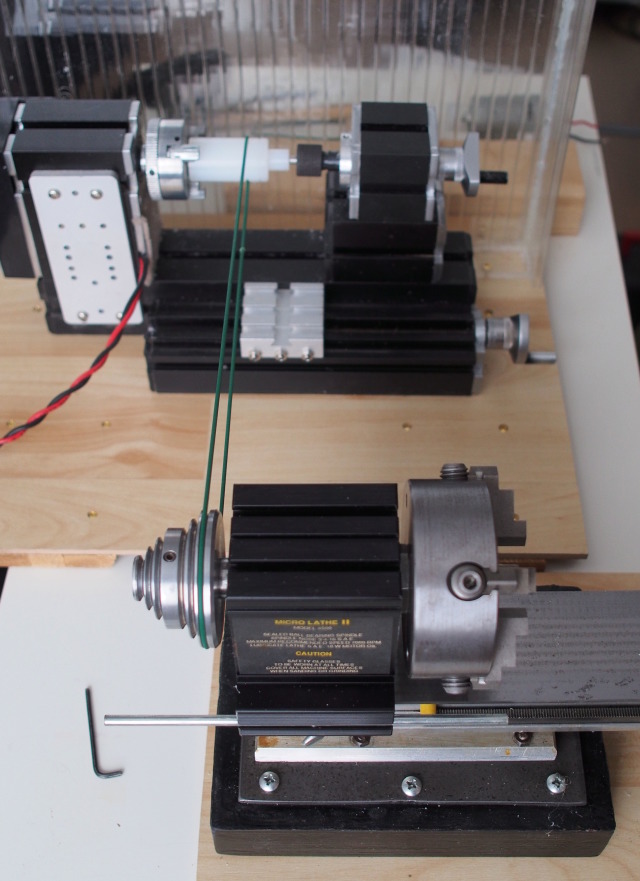

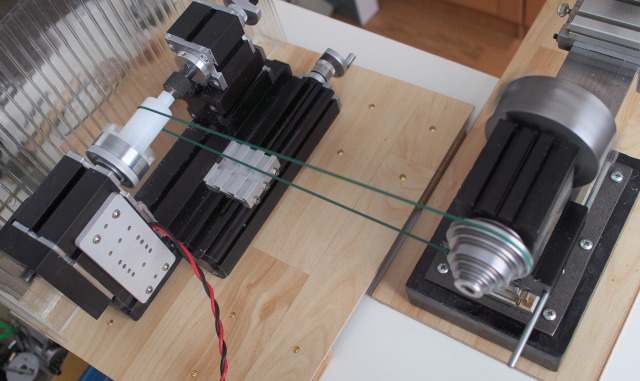

So, I got my Taig lathe mounted and it needs power. It crossed my mind that the Unimat has a working motor, mounts, and ability to hold onto something that will turn a belt. If I could use the ML to power the Taig as a bootstrap, I can test it out and possibly make better motor mounting bits.

I had an earlier PA6 spigot project piece that I turned into a pulley by making a suitable groove in the remaining stock. The profile is probably not what it should be as I used one of my testing toolbits to cut it and not a sharp and/or profiled tool. I also welded up a suitably long belt loop.

I tested running first with a 5 V supply and various pulley speeds, then 12 V. Turning a random piece of square plastic round left quite rough a finish with my jittery handwheeling and slow-ish revs. The finish was much better with 12V and resulting higher revs and torque. Belt will slip on load, though.

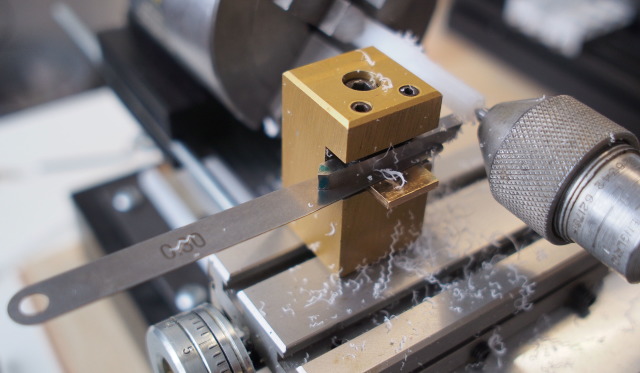

I used a 4 mm center from the Unimat in the drill chuck for my tests. Otherwise there would not be much room for carriage to move between headstock stop (before toolpost hits chuck) and carriage hitting the tailstock. I can see why someone had wanted to make a longer ram.

At the moment I only have 4mm tools that I can't angle very well because of spacing. I'm using a nominally 2 mm bit of brass and a 0.30 mm feeler blade as shims. The centre height is still probably a bit low. Maybe that 0.05 mm would be worth trying (25.4 / 4 = 6.35). I'd need to face something harder to find out how much it's off and if I care. I've ordered 6 mm square HSS and that might need a small shim as well. Alternatively, it might be possible to shim up the tool holder if I had suitable sheet stock.

I also thought that since I have a four-jaw, I might be able to face some square stock accurately enough to raise the Unimat steel toolholder to suitable height. It's maybe off some 20 mm or so.

I made lots of plastic chips today. Now, how could I mount and use a different motor?