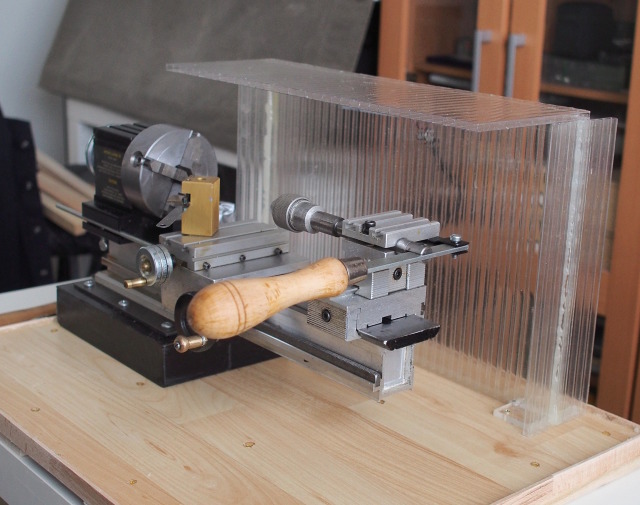

Taig lathe power and transmission improvement

The Taig lathe I recently got needs a usable motor and power supply. I've made some temporary improvements to enable me to run the lathe while I scrounge for more parts so I can make things.

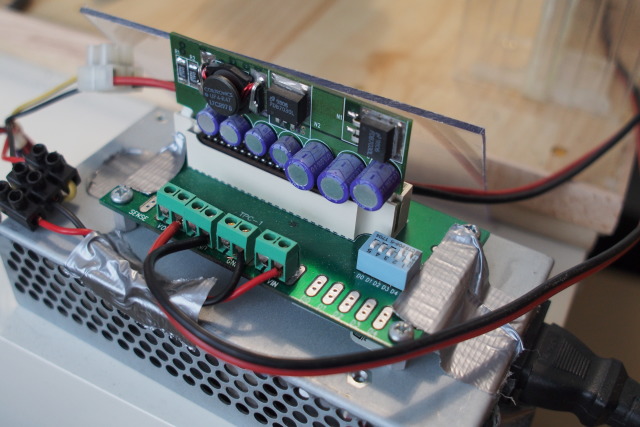

Power supply

After the initial tests with NiCd packs, I tried various power supplies and arrangements and determined that running open loop with this motor would not be very comfortable. I did find a nice switch, a supply from some networking equipment, and a beefy regulator I had from way back and these seem to give tolerable operation when set up for 2.5 V.

It desperately needs more reduction from motor to spindle, though. The revs climb too much unloaded and bog down too much when loaded (high KV of brushed motor plus low torque at the low voltage).

I tested a few retired AC motors as well and found out they were retired for good reasons. So I would continue with the drill motor for now and improve the power and transmission.

Yes, I should really put my actual training to use and set up some speed sensors and PWM control with feedback. Any day now.

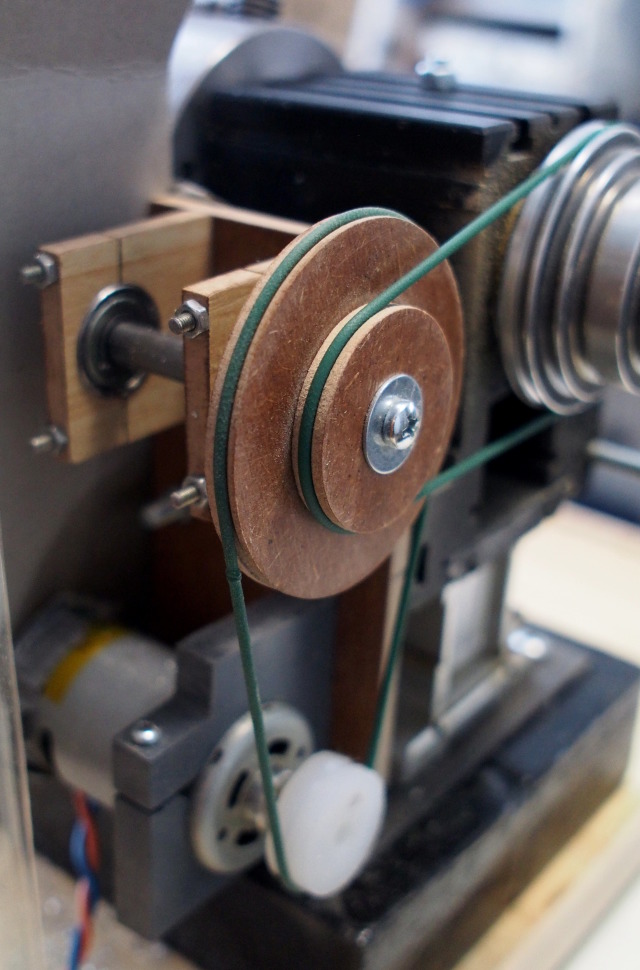

Gearing down

Hoping for a more favourable gearing, I made a jack shaft out of the 8 mm steel rod I use. It's some kind of simple structural steel, but small enough to pass through the entire headstock spindle assembly and large enough to make useful size spigots and still take internal threading.

I bored some split bearing blocks and cut new mounting plate from some floor laminate. I also cut a pair of discs from it using the largest and smallest hole saws I own. The hole saws leave a center hole so I turned down a spigot that was a reasonable fit and put in an internal thread for a bolt to hold the discs in place so I could turn the outside and make some belt grooves. The pair will be held by a screw to the shaft making pulleys for motor and headstock belts. The reductions will be roughly 1:2 and 1:2 making 1:4 total.

I welded up new belts from the 2 mm PU material and put it all together. The motor works much more reasonably now and the voltage can be ramped up a bit to somewhere over 3 V. 5 V still makes for slightly high unloaded speed especially for poorly balanced objects like the bearing blocks and clamps that I expect to be making a lot of.

After a while and a few stalls with the belt pulley slipping, the small wheel actually melted a spot in the belt and it eventually snapped. I took the second smallest hole saw I own and made a slighly bigger small wheel and that pair has been running quite well since with a fresh belt. I'm quickly running out of 2 mm belt material at this pace.

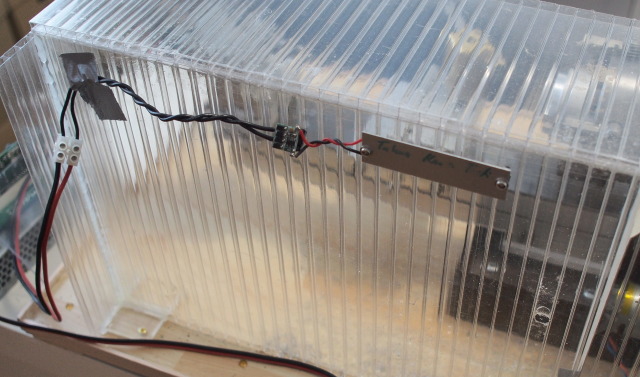

Raising some shields

I've also put up more shielding to keep the chips in line. I'd like some sort of movable transparent shield on the front side to stop it throwing the occasional cutting fluid droplet and chip at me.

The back wall also makes for an easy place to hang some lighting. It's made up of bits of those chinese halogen lamp replacement bits and totals 3 W of LEDs and runs happily off 12 V from the power supply. I picked this over a LED strip for some reason. More or alternative lights are arranged easily enough. I've also added a little glare shield in the top lid made from Al tape.

I'm able to run the lathe with modest power, speed, visibility, and comfort. It will certainly be improved with time, though.

No full setup image was taken at this point, it seems. Sorry about that. The earlier jack shaft picture shows a cardboard wall I put up between the space behind the bed where the chips accumulate and the space behind the headstock where the motor and belts live. That's also working quite well.

The entire back wall could perhaps be moved right so the side is in line with the headstock face. There's no need to have wall behind the headstock part if there's no chips. That would even leave more room for motor, electronics, fan, or whatever.

There should be more posts coming up once I get the writing done.